Strategic Management - Environmental Analysis and Diagnosis

Value Chain Analysis - Internal Analysis

Posted On :

The resources audit provides an understanding of an organization’s capabilities.

Value Chain Analysis

The resources audit provides an understanding of an organization’s capabilities. The next step is to identify how the organizational activities contribute to the value - the price the customers are willing to pay for the goods and services of the organization. If this value exceeds the costs of performing those activities, company is said to be profitable, otherwise it is a loss making company. Therefore to achieve the long run objective of maximization of wealth and short –run goals of generating reasonable profits, it is imperative that the company should gain a competitive edge over its competitors.

“To gain a competitive advantage, a company must either perform value – creation functions at a lower cost then its rivals or perform them in a way that leads to differentiation and a premium price. To do either, it must have a distinctive competence in one or more of its value – creation functions. If it has significant weaknesses in any of these functions, it will be at a competitive disadvantage”

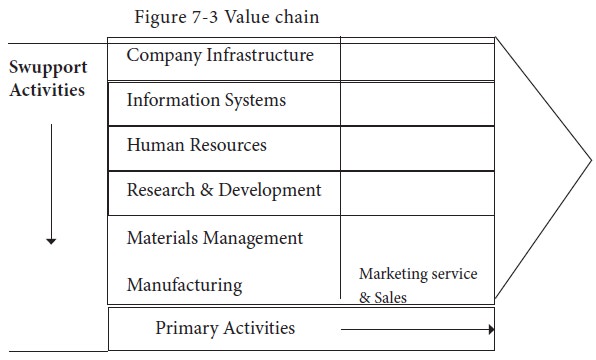

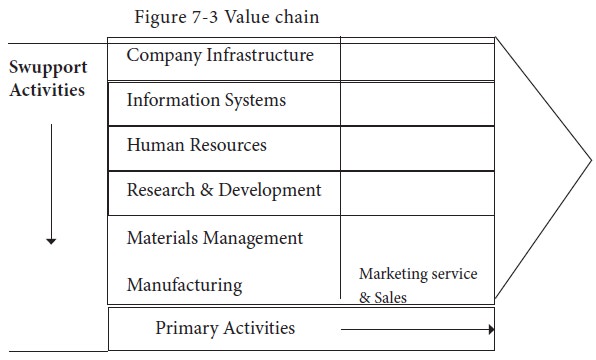

Michael Porter suggested the concept of “value – chain” that sequences the activities related with creation of value (figure 7-3). These activities can be divided between

3. Outbound logistics (activities concerned with

collection, storage and physical distribution of finished goods to the

consumers)

4. Marketing and sales (activities concerned with advertising, selling, administration of sales personnel, etc.)

5. Service (activities that enhance or maintain the value of a product / service, such as installation, repair, training, etc.)

Some others classify primary activities into two main functions

1. Manufacturing (physical creation of the product)

2. Marketing (concerned with marketing, delivery and after sales service)

The support activities that provide inputs and infrastructure for primary activities of manufacturing and marketing are classified as follows

1. Material management activities

2. Research and Development activities

3. Human Resources activities

4. Information systems activities

5. Company infrastructure activities

Material Management activities are concerned with procurement, storage and issuance of material to the production departments. The inventory control that aims at keeping uninterrupted supply of material at minimum associated costs is undertaken under this function.

Research and Development activities permeate manufacturing as well as marketing activities. It aims at developing new products or process technology that provide additional benefits to customers, improve quality, lower the cost of manufacturing and ultimately contribute to the creation of value.

The human resource activities aim at meeting the personnel requirement of manufacturing and marketing departments by proper selection of staff, their training and development.

The information system activities ensure efficient and expeditious flow of needed information to the concerned managers for taking decisions and actions.

The infrastructure activities embrace all other activities like finance, legal, public relations, etc which are essential for the company.

It involves the following steps. Figure 7-4 depicts a corporate val-ue chain.

1. Examine each product lines value chain in terms of various activities involved in producing a product or service. Examine the S&W

2. Identify the linkages in product lines value chain. Ex: quality control, check 100% instead of 10% to avoid repairs and returns

3. Examine the synergies among value chains of different product lines or SBUS. Ex: Cost of advertising, production etc jointly will be cheaper

Figure 7.4 A Corporate value chain

JR Galbraith suggests the other method of analyzing a firm’s value chain. This analysis helps ascertain where a firm’s products are located in the overall value chain. An illustrative value chain is given in Figure 7-5 below. Henry ford I during 1920s and 1930s did this Value Chain analysis. Visitors watched the entire process from an elevated walk way.

This can be split into two

Upstream – Ex: Refers to oil exploration, drilling, moving crude to refiners

Downstream – Ex: Refining the oil + transporting and marketing to distributors & retailers.

Some companies are experts in down stream like P&G & Texaco and some in upstream like British Petroleum.

According to Galbraith firm’s centre of gravity is usually the point at which the company started. After a firm establishes well in this point it can move forward or backward along the value chain to reduce costs, access to raw material and guarantee distribution. This process is

The resources audit provides an understanding of an organization’s capabilities. The next step is to identify how the organizational activities contribute to the value - the price the customers are willing to pay for the goods and services of the organization. If this value exceeds the costs of performing those activities, company is said to be profitable, otherwise it is a loss making company. Therefore to achieve the long run objective of maximization of wealth and short –run goals of generating reasonable profits, it is imperative that the company should gain a competitive edge over its competitors.

Charles W.L. Hill and Gareth R. Jones maintain

“To gain a competitive advantage, a company must either perform value – creation functions at a lower cost then its rivals or perform them in a way that leads to differentiation and a premium price. To do either, it must have a distinctive competence in one or more of its value – creation functions. If it has significant weaknesses in any of these functions, it will be at a competitive disadvantage”

Michael Porter suggested the concept of “value – chain” that sequences the activities related with creation of value (figure 7-3). These activities can be divided between

(a) | Primary activities, and |

(b) | Support activities. |

The primary activities are concerned with physical

creation of the prod-uct, its marketing and delivery to buyers and after-sales

service. The support activities provide the inputs and infrastructure for the

primary activities.

Some authors classify primary activities into five categories

1. Inbound logistics (activities concerned with receiving, storing and distributing the material, inventory control, warehousing, etc.)

2. Operations (activities concerned with transformation of inputs into final product or service: for example, matching, packing, assembly testing etc.)

Primary Activities

Some authors classify primary activities into five categories

1. Inbound logistics (activities concerned with receiving, storing and distributing the material, inventory control, warehousing, etc.)

2. Operations (activities concerned with transformation of inputs into final product or service: for example, matching, packing, assembly testing etc.)

4. Marketing and sales (activities concerned with advertising, selling, administration of sales personnel, etc.)

5. Service (activities that enhance or maintain the value of a product / service, such as installation, repair, training, etc.)

Some others classify primary activities into two main functions

1. Manufacturing (physical creation of the product)

2. Marketing (concerned with marketing, delivery and after sales service)

Support Activities

The support activities that provide inputs and infrastructure for primary activities of manufacturing and marketing are classified as follows

1. Material management activities

2. Research and Development activities

3. Human Resources activities

4. Information systems activities

5. Company infrastructure activities

Material Management activities are concerned with procurement, storage and issuance of material to the production departments. The inventory control that aims at keeping uninterrupted supply of material at minimum associated costs is undertaken under this function.

Research and Development activities permeate manufacturing as well as marketing activities. It aims at developing new products or process technology that provide additional benefits to customers, improve quality, lower the cost of manufacturing and ultimately contribute to the creation of value.

The human resource activities aim at meeting the personnel requirement of manufacturing and marketing departments by proper selection of staff, their training and development.

The information system activities ensure efficient and expeditious flow of needed information to the concerned managers for taking decisions and actions.

The infrastructure activities embrace all other activities like finance, legal, public relations, etc which are essential for the company.

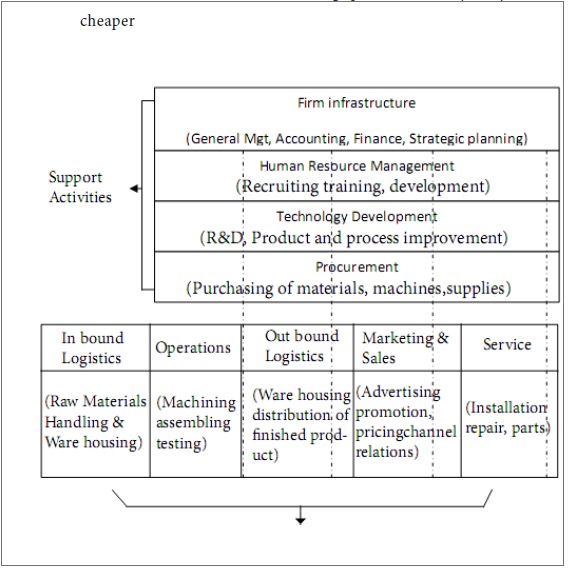

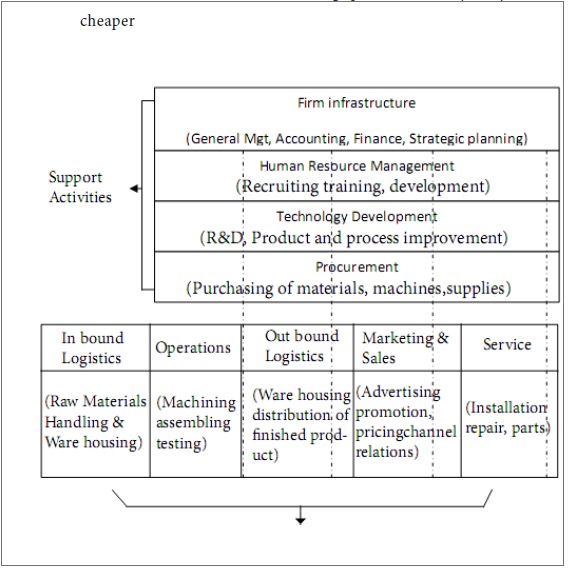

Corporate Value Chain Analysis

It involves the following steps. Figure 7-4 depicts a corporate val-ue chain.

1. Examine each product lines value chain in terms of various activities involved in producing a product or service. Examine the S&W

2. Identify the linkages in product lines value chain. Ex: quality control, check 100% instead of 10% to avoid repairs and returns

3. Examine the synergies among value chains of different product lines or SBUS. Ex: Cost of advertising, production etc jointly will be cheaper

Primary Activities

Figure 7.4 A Corporate value chain

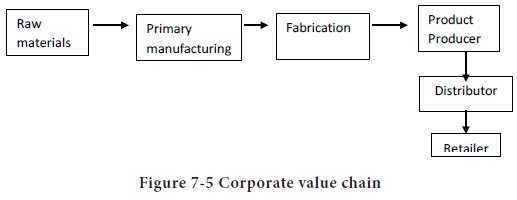

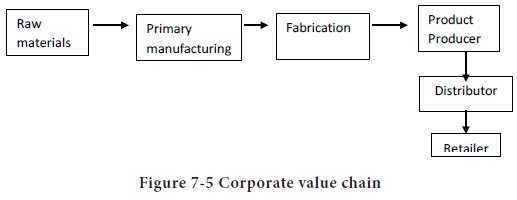

JR Galbraith suggests the other method of analyzing a firm’s value chain. This analysis helps ascertain where a firm’s products are located in the overall value chain. An illustrative value chain is given in Figure 7-5 below. Henry ford I during 1920s and 1930s did this Value Chain analysis. Visitors watched the entire process from an elevated walk way.

Industry Value Chain Analysis

This can be split into two

Upstream – Ex: Refers to oil exploration, drilling, moving crude to refiners

Downstream – Ex: Refining the oil + transporting and marketing to distributors & retailers.

Some companies are experts in down stream like P&G & Texaco and some in upstream like British Petroleum.

According to Galbraith firm’s centre of gravity is usually the point at which the company started. After a firm establishes well in this point it can move forward or backward along the value chain to reduce costs, access to raw material and guarantee distribution. This process is

Tags : Strategic Management - Environmental Analysis and Diagnosis

Last 30 days 982 views