Strategic Management - Functional Strategy

Logistics Strategies - Logistics And Information Strategies

Posted On :

The process of getting goods to customers has traditionally been called physical distribution.

Logistics Strategies

The process of getting goods to customers has traditionally been called physical distribution. It includes location of plants and warehousing, transportation mode, inventory and packing. The systems concept of physical distribution takes into account the interdependence of costs of each activity. It is now being termed as integrated market logistics which can be conceptualized as the series of sales-satisfying

Order processing

Ware housing

Inventory

Transportation

Recently, the concept of integrated market logistics system is referred to as supply chain management, which is broader in it s scope. It is concerned with all the flows starting from supplier to manufacturer to customer. As such integrated market logistics system is a subset of supply chain management of a firm.

Responsive logistical service advances customer satisfaction and creates the opportunity for closer and more profitable buyer-seller relationships.. Logistics service is often ranked by buyers right behind “quality” as a criterion for selecting a vendor

Logistics creates place and time utilities to consumers. Companies lose their customers when they fail to supply goods on time.

Experts believe that substantial savings can be effected in physical distribution area, which has been described as ‘the lost frontier for cost economies’. Physical distribution decisions when uncoordinated, result in high cost. There is a need to make use of modern decision tools for coordinating inventory levels, transportation modes, and plant, ware house and store locations.

It is not only a cost, it is a potent tool in competitive marketing. Companies can attract additional customers by offering better service or lower price through improvements in physical distribution.

The objective of physical distribution is getting the right goods to the right places at the right time for the least cost. Evidently, this involves a trade—off between customer service and cost.

Maximum customer service implies large inventories, premium transportation and multiple warehouses all of which raise distribution cost. Minimum distribution cost implies cheap transportation, low stocks and few ware houses.

As such physical distribution decisions must aim at optimization of total system and not the sub optimization at the subsystem levels i.e., order processing, warehousing, inventory and transportation.

Marketers have to decide their service standards based on key information about customers and competitors.

What the customers are looking for?

What the competitors are offering?

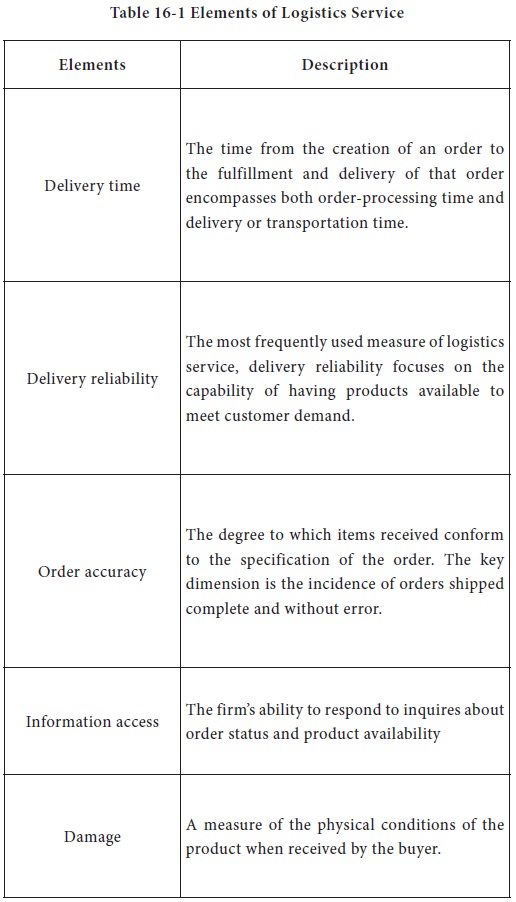

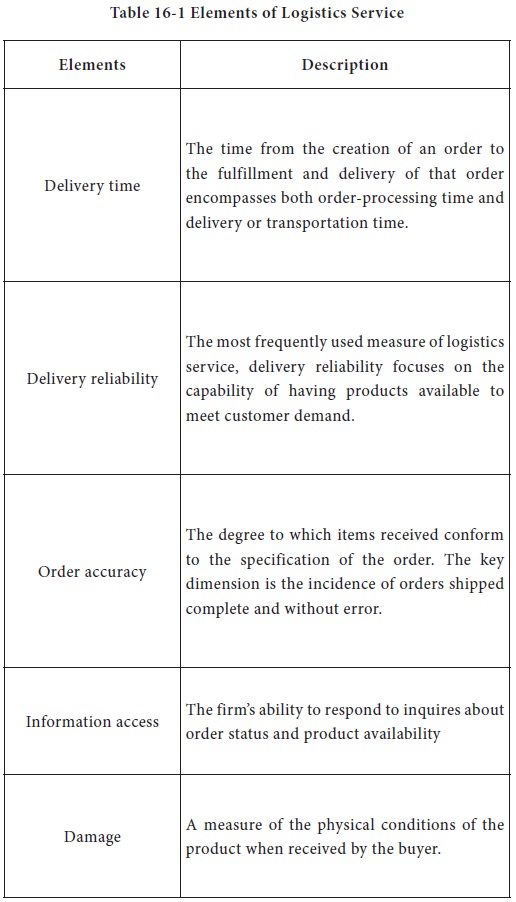

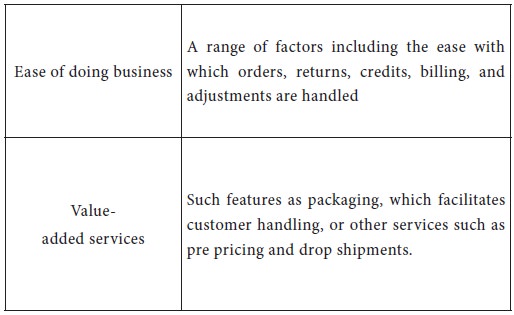

Table 16-1 describes the various elements of service. Typical service standards are:

Put the product within an arms length of customers

To deliver at least 95 per cent of the dealer’s orders within seven days of the receipt

To ensure that damage to merchandise in transit does not exceed 5 percent

However, not all products or all customers require the same level of logistical service.

Many business products that are made to order—such as heavy machinery—have relatively low logistical service requirements. Others, such as replacement parts, components, and subassemblies, require extremely demanding logistical performance. Similarly, customers may be more or les responsive to varying levels of logistical service.

How much

stock should be held? (inventory), and

How should goods be shipped? (transportation).

Source

Marshall L. Fisher “What is the Right Supply Chain for your Product?”, Harvard Business Review (March – April 1997), 83-93.

To understand how a company can improve supply chain performance in terms of responsiveness and efficiency, one has to examine the four drivers of supply chain performance: facilities(warehouses), inventory, transportation, and information. These drivers not only determine the supply chains performance in term of responsiveness and

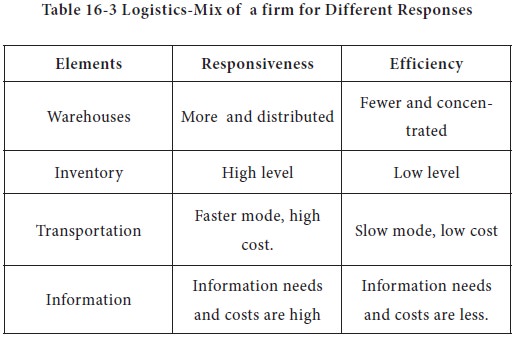

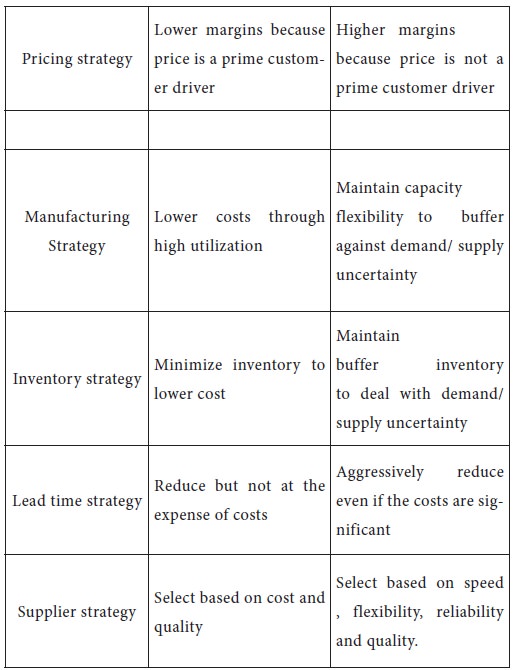

For each of the individual drivers, supply chain managers must make a trade-off between efficiency and responsiveness. The combined impact of these drivers then determines the responsiveness and efficiency of the entire supply chain. Table 16-3 shows the logistics-mix for responsiveness and efficiency.

Creating

superior value

Superior value can be created by meeting service expectations of customers and reducing the costs of logistics.

(i) Meeting service expectations

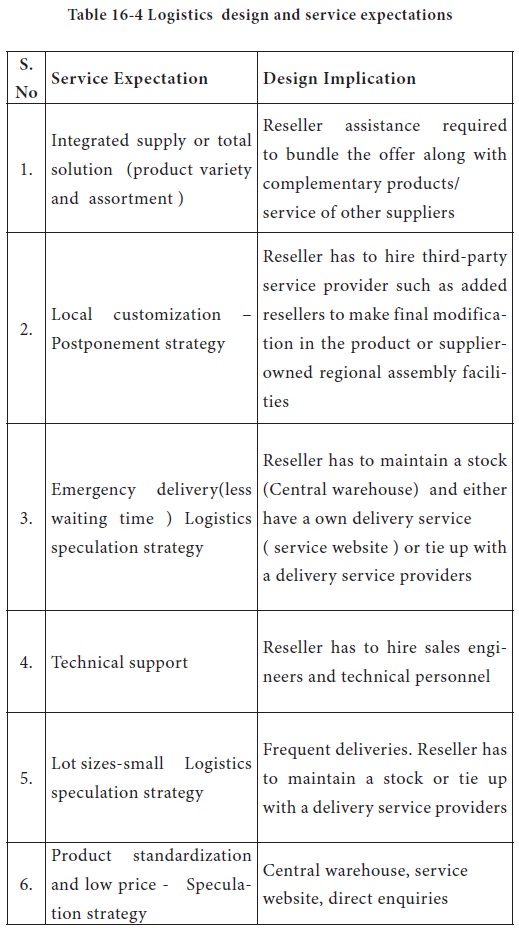

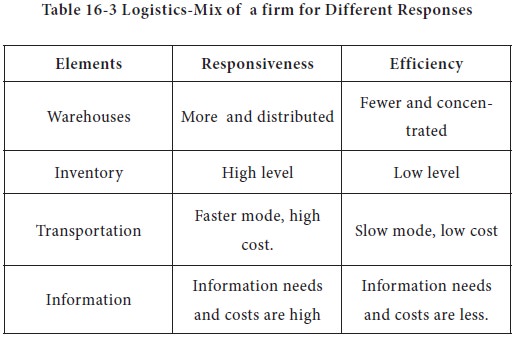

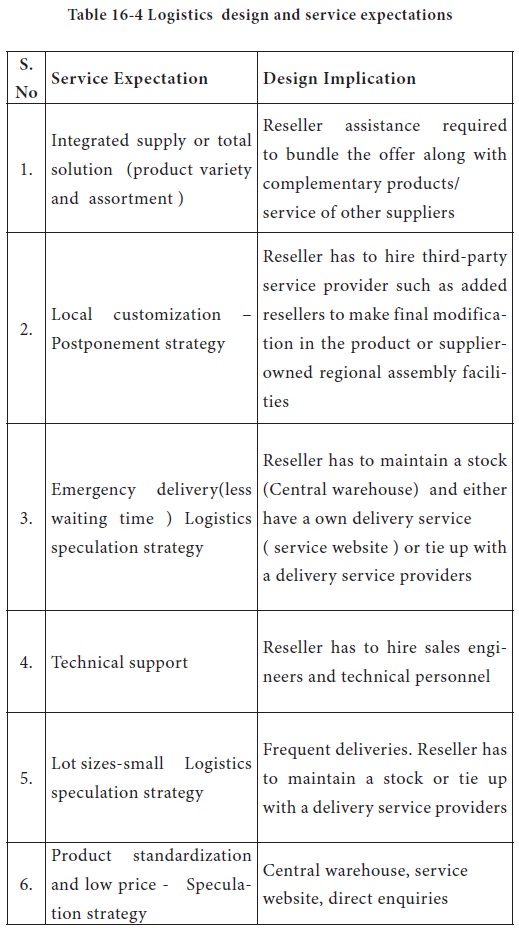

Services expected by customers and the possible logistics design implications are given in Table 16-4.

(i) Postponement strategy

When the key element in a supplier firm’s proposed value proposition is local customization, a postponement strategy is appropriate. Here, the supplier delays final changes to an offering’s form until the last possible moment through the use of third-party service providers or supplier-owned regional assembly facilities. For example, if physical modifications to products are necessary, the supplier firm might partner with local assemblers, fabricators, or value-added resellers.

(ii) Speculation strategy

When low price and product standardization are the key elements of the value proposition, a speculation strategy is recommended. In term of physical products, a supplier firm speculates by manufacturing them in a large lots, storing them in inventory in a central location in anticipation of orders, and shipping them in bulk directly to customer firms or to reseller for sale to other customer firms in small lots. To speculate with technical support service, the supplier might provide customer firms with self-help manuals or software, operate an Internet-base technical service site, or direct customer inquires to a telephone support center.

Logistics speculation strategy. When the key element of the value proposition is emergency delivery, managers turn to logistics speculation whereby a vendor produces standardized products and either stocks inventory in supplier-owned local distribution centers or relies on overnight delivery services, to ship them from a centralized warehouse.

The process of getting goods to customers has traditionally been called physical distribution. It includes location of plants and warehousing, transportation mode, inventory and packing. The systems concept of physical distribution takes into account the interdependence of costs of each activity. It is now being termed as integrated market logistics which can be conceptualized as the series of sales-satisfying

Order processing

Ware housing

Inventory

Transportation

Recently, the concept of integrated market logistics system is referred to as supply chain management, which is broader in it s scope. It is concerned with all the flows starting from supplier to manufacturer to customer. As such integrated market logistics system is a subset of supply chain management of a firm.

Significance of logistics

Responsive logistical service advances customer satisfaction and creates the opportunity for closer and more profitable buyer-seller relationships.. Logistics service is often ranked by buyers right behind “quality” as a criterion for selecting a vendor

Time factor

Logistics creates place and time utilities to consumers. Companies lose their customers when they fail to supply goods on time.

Cost factor

Experts believe that substantial savings can be effected in physical distribution area, which has been described as ‘the lost frontier for cost economies’. Physical distribution decisions when uncoordinated, result in high cost. There is a need to make use of modern decision tools for coordinating inventory levels, transportation modes, and plant, ware house and store locations.

Promotion factor

It is not only a cost, it is a potent tool in competitive marketing. Companies can attract additional customers by offering better service or lower price through improvements in physical distribution.

Objectives

The objective of physical distribution is getting the right goods to the right places at the right time for the least cost. Evidently, this involves a trade—off between customer service and cost.

Maximum customer service implies large inventories, premium transportation and multiple warehouses all of which raise distribution cost. Minimum distribution cost implies cheap transportation, low stocks and few ware houses.

As such physical distribution decisions must aim at optimization of total system and not the sub optimization at the subsystem levels i.e., order processing, warehousing, inventory and transportation.

Customer service

Marketers have to decide their service standards based on key information about customers and competitors.

What the customers are looking for?

What the competitors are offering?

Table 16-1 describes the various elements of service. Typical service standards are:

Put the product within an arms length of customers

To deliver at least 95 per cent of the dealer’s orders within seven days of the receipt

To ensure that damage to merchandise in transit does not exceed 5 percent

However, not all products or all customers require the same level of logistical service.

Many business products that are made to order—such as heavy machinery—have relatively low logistical service requirements. Others, such as replacement parts, components, and subassemblies, require extremely demanding logistical performance. Similarly, customers may be more or les responsive to varying levels of logistical service.

Source

Jonathon L. S. Byrnes, William C. Copacino, and Peter Metz, “Forge Service into a Weapon with Logistics,” Transportation & Distribution, Presidential Issue 28 (September 1987): p.46.

The next step is developing a cost function for a service level as shown below.

D = T + FW + VW + S

Where

D = total distribution cost of proposed system T = total freight cost

FW = total fixed warehouse costs

VW = total variable warehouse costs

S = Total cost of sales lost due to average delivery delay under proposed system.

The company should aim at minimizing the distribution cost of reaching a target level of customer service.

Key Decisions

We will now examine the four major decision issues

How should orders be handled? (order processing)

Where should stocks be located? (warehousing)

Jonathon L. S. Byrnes, William C. Copacino, and Peter Metz, “Forge Service into a Weapon with Logistics,” Transportation & Distribution, Presidential Issue 28 (September 1987): p.46.

Cost

The next step is developing a cost function for a service level as shown below.

D = T + FW + VW + S

Where

D = total distribution cost of proposed system T = total freight cost

FW = total fixed warehouse costs

VW = total variable warehouse costs

S = Total cost of sales lost due to average delivery delay under proposed system.

The company should aim at minimizing the distribution cost of reaching a target level of customer service.

Key Decisions

We will now examine the four major decision issues

How should orders be handled? (order processing)

Where should stocks be located? (warehousing)

How should goods be shipped? (transportation).

1. Order Processing

The first phase in physical distribution is order – shipping – billing cycle. A customer order initiates several steps

i. Order department prepares multi copy invoices and dispatches them to various departments.

ii. Order is checked with available stock. Items out of stock are back ordered

iii. Items are shipped. Shipped items are accompanied by shipping and billing documents with copies going to various departments.

The whole process is now expedited with the help of computers by warehousing

2. Warehousing

A storage function is necessary because the production will be more than customer orders in general. Striking a balance between customer service standards and distribution costs, marketers has to

i. Decide on a desirable number of stocking locations depending upon the markets the firm intends to serve

ii. Choose the type of warehouses. Today a variety of warehouses, with advanced material handling systems and storage facilities are available.

3. Inventory

Inventory management requires decisions relating to

i. Level of stock – Determining optimum order quantity

ii. Time of ordering – Reorder point

iii. Minimum stock level to meet emergencies – safety stock

Today, just – in – time production practices and product customization are changing the inventory planning practices

The first phase in physical distribution is order – shipping – billing cycle. A customer order initiates several steps

i. Order department prepares multi copy invoices and dispatches them to various departments.

ii. Order is checked with available stock. Items out of stock are back ordered

iii. Items are shipped. Shipped items are accompanied by shipping and billing documents with copies going to various departments.

The whole process is now expedited with the help of computers by warehousing

2. Warehousing

A storage function is necessary because the production will be more than customer orders in general. Striking a balance between customer service standards and distribution costs, marketers has to

i. Decide on a desirable number of stocking locations depending upon the markets the firm intends to serve

ii. Choose the type of warehouses. Today a variety of warehouses, with advanced material handling systems and storage facilities are available.

3. Inventory

Inventory management requires decisions relating to

i. Level of stock – Determining optimum order quantity

ii. Time of ordering – Reorder point

iii. Minimum stock level to meet emergencies – safety stock

Today, just – in – time production practices and product customization are changing the inventory planning practices

4. Transportation

Marketers have to make careful choice of transportation mode and organizations. In choosing a transportation mode for a particular

Speed

Frequency

Dependability

Capability

Availability

Cost

Supply chain strategy determines the nature of procurement of raw materials, transportation of materials to and from the company, manufacture of the product or operation to provide the service, and distribution of the product to the customer, along with any follow-up service. From a value chain perspective, supply chain strategy specifies what operations, distribution, and service will try to do particularly well. Additionally, in each company, strategies will also be devised for finance, accounting, information technology, and human resources. The value chain emphasizes the close relationship between all the functional strategies within a company. .

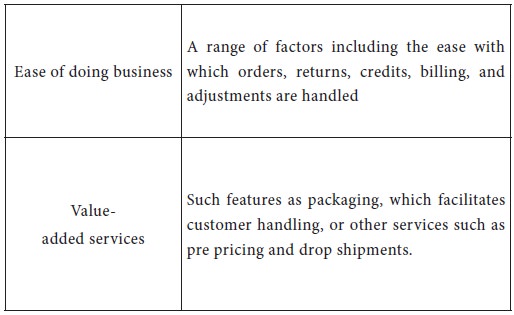

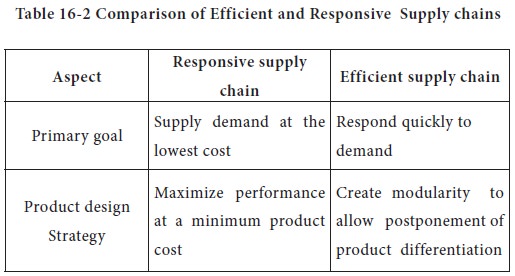

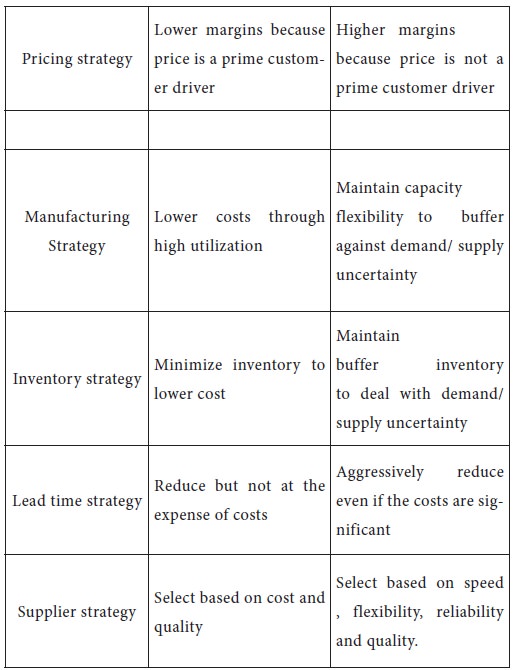

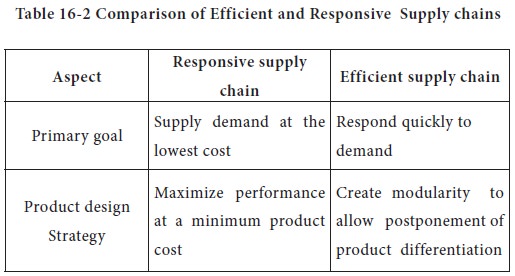

The strategic fit requires that a company achieve the balance between responsiveness and efficiency in its supply chain that best meets the needs of the company’s competitive strategy. Table 16-2 makes a comparison of efficient and responsive supply chains.

Marketers have to make careful choice of transportation mode and organizations. In choosing a transportation mode for a particular

Speed

Frequency

Dependability

Capability

Availability

Cost

Logistics and supply chain strategies

Supply chain strategy determines the nature of procurement of raw materials, transportation of materials to and from the company, manufacture of the product or operation to provide the service, and distribution of the product to the customer, along with any follow-up service. From a value chain perspective, supply chain strategy specifies what operations, distribution, and service will try to do particularly well. Additionally, in each company, strategies will also be devised for finance, accounting, information technology, and human resources. The value chain emphasizes the close relationship between all the functional strategies within a company. .

The strategic fit requires that a company achieve the balance between responsiveness and efficiency in its supply chain that best meets the needs of the company’s competitive strategy. Table 16-2 makes a comparison of efficient and responsive supply chains.

Marshall L. Fisher “What is the Right Supply Chain for your Product?”, Harvard Business Review (March – April 1997), 83-93.

To understand how a company can improve supply chain performance in terms of responsiveness and efficiency, one has to examine the four drivers of supply chain performance: facilities(warehouses), inventory, transportation, and information. These drivers not only determine the supply chains performance in term of responsiveness and

For each of the individual drivers, supply chain managers must make a trade-off between efficiency and responsiveness. The combined impact of these drivers then determines the responsiveness and efficiency of the entire supply chain. Table 16-3 shows the logistics-mix for responsiveness and efficiency.

Superior value can be created by meeting service expectations of customers and reducing the costs of logistics.

(i) Meeting service expectations

Services expected by customers and the possible logistics design implications are given in Table 16-4.

(i) Postponement strategy

When the key element in a supplier firm’s proposed value proposition is local customization, a postponement strategy is appropriate. Here, the supplier delays final changes to an offering’s form until the last possible moment through the use of third-party service providers or supplier-owned regional assembly facilities. For example, if physical modifications to products are necessary, the supplier firm might partner with local assemblers, fabricators, or value-added resellers.

(ii) Speculation strategy

When low price and product standardization are the key elements of the value proposition, a speculation strategy is recommended. In term of physical products, a supplier firm speculates by manufacturing them in a large lots, storing them in inventory in a central location in anticipation of orders, and shipping them in bulk directly to customer firms or to reseller for sale to other customer firms in small lots. To speculate with technical support service, the supplier might provide customer firms with self-help manuals or software, operate an Internet-base technical service site, or direct customer inquires to a telephone support center.

Logistics speculation strategy. When the key element of the value proposition is emergency delivery, managers turn to logistics speculation whereby a vendor produces standardized products and either stocks inventory in supplier-owned local distribution centers or relies on overnight delivery services, to ship them from a centralized warehouse.

Tags : Strategic Management - Functional Strategy

Last 30 days 1043 views