Operations Management - Introduction to Operations Management

Process Planning - Introduction to Operations Management

Posted On :

Any business, the success predominantally depenps upon the effective production/operations process.

Process Planning

Any business, the success predominantally depenps upon the effective production/operations process. There are numerous types of production processess and there are also many ways of classifying or grouping them for descriptive purposes. Classifying production/ operations processes by their characteristics can provide valuable insights into how they should be managed.

In general, the processes by which goods and services are produced can be categorised in two traditional ways.

1. Firstly, we can identify continuous, repetitive, intermittent and job shop production process.

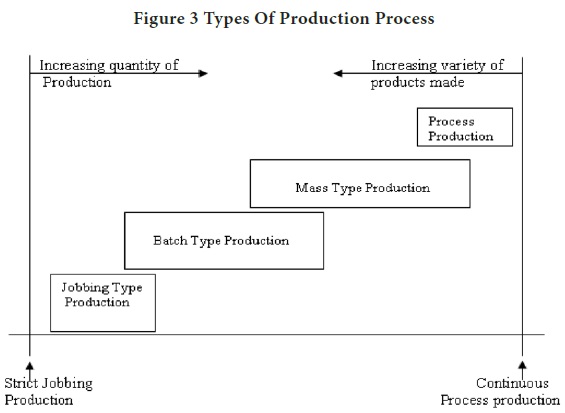

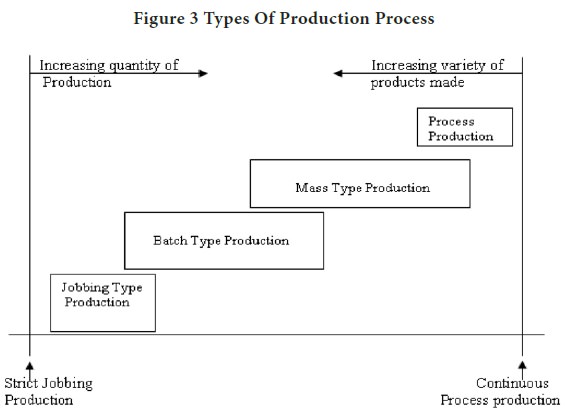

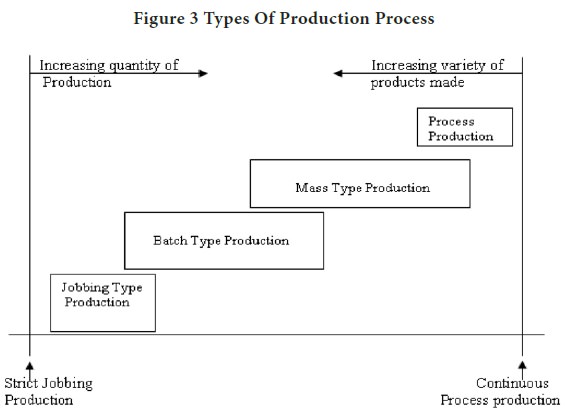

2. Second and similar classification divides production processes into Process production, Mass production, Batch production and jobbing production.

We will breifly introduce these methods in the following paragraphs.t

A wide variety of customized products are made by a highly skilled workforce using general-purpose equipment. These processes are referred to as jumbled-flow processes because there are many possible routings through the process.

Examples: Home renovating firm, stereo repair shop, restaurants.

A mixture of general-purpose and special-purpose equipment is used to produce small to large batches of products.

Examples: Clothing and book manufacturers, winery, caterer.

The product or products are processed in lots, each item of production passing through the same sequence of operations, i.e. several standardized products follow a predetermined flow through sequentially dependent work centers. Workers typically are assigned to a narrow range of tasks and work with highly specialised equipment.

Examples: Automobile and computer assembly lines, insurance home office.

Commodity like products flow continuously through a linear process. This type of process will theoretically run for 24 hrs/day, 7 days/ week and 52 weeks/year and, whilst this is often the objective, it is rarely achieved.

Examples: chemical, oil, and sugar refineries, power and light utilities.

These four categories represent points on continuum of process organisations. Processes that fall within a particular category share many

The second and similar classification divides production processes into:

Processes that operate continually to produce a very high volume of a standard product are termed “Processes”. This type of process involves the continuous production of a commodity in bulk, often by chemical rather than mechanical means, such as oil and gas. Extra examples of a continuous processes oil refinery, electricity production and steel making.

It is conceptually similar to process production, except that discrete items such as motorcars and domestic appliances are usually involved. A single or a very small range of similar items is produced in very large numbers. In other words, processes that produce high-volume and low-variety products are termed line or mass processes. Because of the high volumes of product it is cost-effective to use specialised labour and equipment.

Processes that produce products of medium variety and medium volume are termed “batch processes”. It occurs where the number of discrete items to be manufactured in a period is insufficient to enable mass production to be used. Similar items are, where possible, manufactured together in batches. In other words, batch processes cover a relatively wide range of volume and variety combination. Products are grouped into batches whose batch size can range from two to hundreds.

Processes that produce high-variety and low-volume products are known as “jobbing”. Although strictly consisting of the manufacture of different products in unit quantities (in practice corresponds to the

a one-of-a-kind production output, such as a new building or developing a new software application. The equipment is typically designed for flexibility and often general purpose, meaning it can be used for many different production requirements.

Often, it is a practice that a firm has more than one type of operating process in its production system to manage the resources optimally. Sometime, the labour may not be available; on other occasion, the raw material may be short; market may slow down or go up exponentially. For instance, a firm may use a repetitive-flow process to produce high-volume parts but use an intermittent-flow process for lower-volume parts.

A link often exists between a firm’s product line and its operating processes. Job shop organisations are commonly utilised when a product or family of products is first introduced. As sales volumes increase and the product’s design stabilises, the process tends to move along the continuum toward a continuous-flow shop. Thus, as products evolve, the nature of the operating processes used to produce them evolves as well.

Any business, the success predominantally depenps upon the effective production/operations process. There are numerous types of production processess and there are also many ways of classifying or grouping them for descriptive purposes. Classifying production/ operations processes by their characteristics can provide valuable insights into how they should be managed.

In general, the processes by which goods and services are produced can be categorised in two traditional ways.

1. Firstly, we can identify continuous, repetitive, intermittent and job shop production process.

2. Second and similar classification divides production processes into Process production, Mass production, Batch production and jobbing production.

We will breifly introduce these methods in the following paragraphs.t

Job shop

A wide variety of customized products are made by a highly skilled workforce using general-purpose equipment. These processes are referred to as jumbled-flow processes because there are many possible routings through the process.

Examples: Home renovating firm, stereo repair shop, restaurants.

Intermittent (batch) flow

A mixture of general-purpose and special-purpose equipment is used to produce small to large batches of products.

Examples: Clothing and book manufacturers, winery, caterer.

Repetitive flow (mass production)

The product or products are processed in lots, each item of production passing through the same sequence of operations, i.e. several standardized products follow a predetermined flow through sequentially dependent work centers. Workers typically are assigned to a narrow range of tasks and work with highly specialised equipment.

Examples: Automobile and computer assembly lines, insurance home office.

Continuous flow (flow shop)

Commodity like products flow continuously through a linear process. This type of process will theoretically run for 24 hrs/day, 7 days/ week and 52 weeks/year and, whilst this is often the objective, it is rarely achieved.

Examples: chemical, oil, and sugar refineries, power and light utilities.

These four categories represent points on continuum of process organisations. Processes that fall within a particular category share many

The second and similar classification divides production processes into:

Process Production

Processes that operate continually to produce a very high volume of a standard product are termed “Processes”. This type of process involves the continuous production of a commodity in bulk, often by chemical rather than mechanical means, such as oil and gas. Extra examples of a continuous processes oil refinery, electricity production and steel making.

Mass Production

It is conceptually similar to process production, except that discrete items such as motorcars and domestic appliances are usually involved. A single or a very small range of similar items is produced in very large numbers. In other words, processes that produce high-volume and low-variety products are termed line or mass processes. Because of the high volumes of product it is cost-effective to use specialised labour and equipment.

Batch Production

Processes that produce products of medium variety and medium volume are termed “batch processes”. It occurs where the number of discrete items to be manufactured in a period is insufficient to enable mass production to be used. Similar items are, where possible, manufactured together in batches. In other words, batch processes cover a relatively wide range of volume and variety combination. Products are grouped into batches whose batch size can range from two to hundreds.

Jobbing Production (Project Type Production)

Processes that produce high-variety and low-volume products are known as “jobbing”. Although strictly consisting of the manufacture of different products in unit quantities (in practice corresponds to the

a one-of-a-kind production output, such as a new building or developing a new software application. The equipment is typically designed for flexibility and often general purpose, meaning it can be used for many different production requirements.

Often, it is a practice that a firm has more than one type of operating process in its production system to manage the resources optimally. Sometime, the labour may not be available; on other occasion, the raw material may be short; market may slow down or go up exponentially. For instance, a firm may use a repetitive-flow process to produce high-volume parts but use an intermittent-flow process for lower-volume parts.

A link often exists between a firm’s product line and its operating processes. Job shop organisations are commonly utilised when a product or family of products is first introduced. As sales volumes increase and the product’s design stabilises, the process tends to move along the continuum toward a continuous-flow shop. Thus, as products evolve, the nature of the operating processes used to produce them evolves as well.

Tags : Operations Management - Introduction to Operations Management

Last 30 days 3052 views